EVS Installation

It can take as little as 10 minutes to install a EVS Glazing panel, compared to over three hours to retro glaze a traditional double glazing panel

It can take as little as 10 minutes to install a EVS Glazing panel, compared to over three hours to retro glaze a traditional double glazing panel

EVS installation is very simple and quick and provides huge satisfaction to those that do it them selves. Tradiational Retro glazing requires a high level of skill, specialised tools, takes a lot of time, and can leave a lot of damage especially to fragile lead lights, timberwork, and paint. It takes less then an hour to install an EVS panel and most of that time is spent on cleaning and preparing the paintwork around the existing window. DIY customers simply need to measure their glass size and email photos and sizes to EVS. The windows are manufactured and sent ready to install.

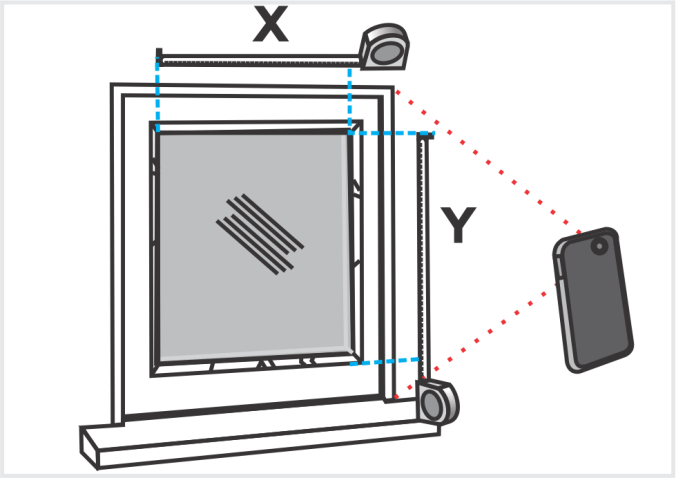

Measure your window by placing your tape measure between the glass clear daylight opening size. First measurement should be across (X) and second measurement up and down (Y). It is important to record this in the right order so that your windows gets manufactured correctly. Include a photo of each window so they can be checked for correct fitting.

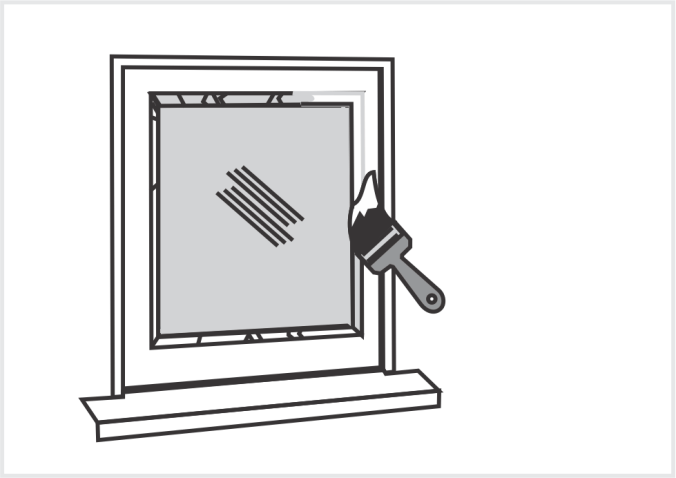

Your window will require some maintenance before adding the EVS panel. If the putty is missing or cracked, then repair it with suitable fillers or paintable silicon. Don't use putty unless you can wait three weeks before it can be painted. You can match the existing paint or use a dark grey colour around the putty edges. Finish by giving the window a very good clean, using quality glass cleaners and razor blades.

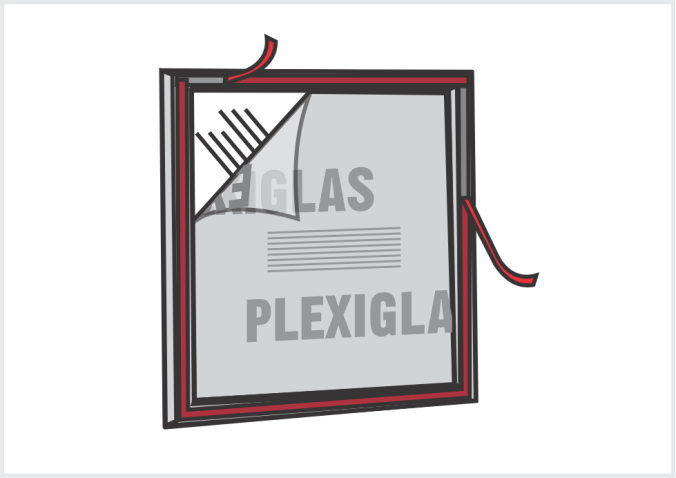

After you receive your EVS Panels, check size by marking 40mm from the edge of the glass, then position your EVS panel between the lines to make sure it sits correctly before you fix it to the window sash. Place a sucker cup on the face side so you don't get fingerprints or dust on the plexiglass. Peel off the Plexiglas protective film, and remove the double sided tape backing, ready to stick onto the window sash.

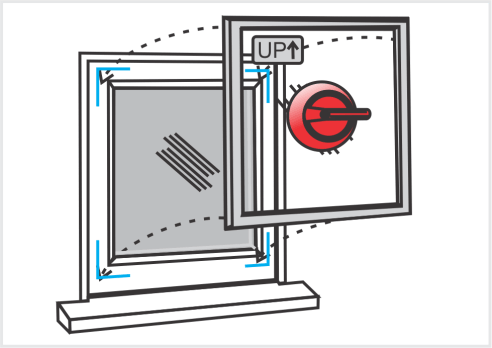

Make sure that the ID sticker is showing the up position and position the window onto the lines that you have drawn on the window Sash. Press the edges firmly onto sash to ensure a good grip. The double sided tape is not permanent fixing and will peel off if not properly secured . It is recommended that you continue to hold the suction cup until your EVS panel is completely pinned to the surface.

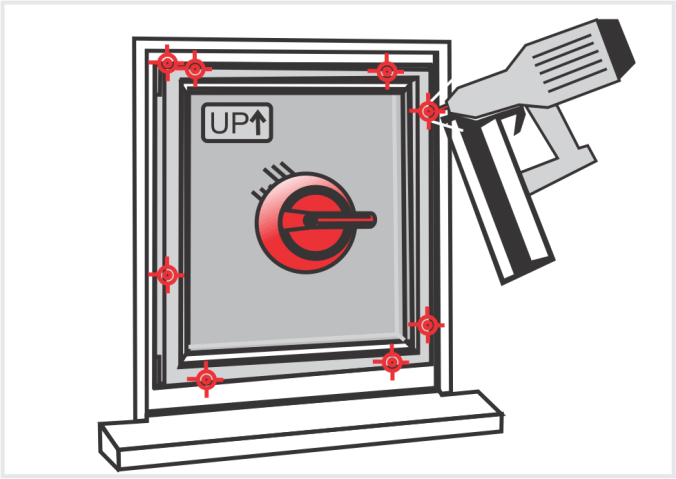

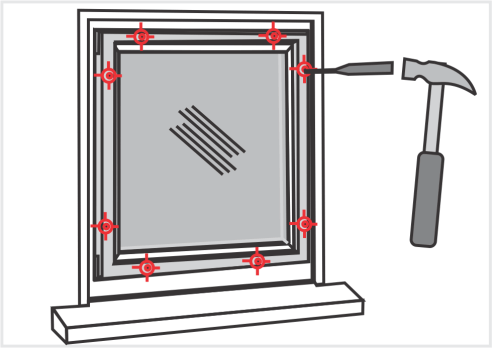

The easiest method of fixing is by using a small battery pin gun. Use 30mm 18 Gauge pins, Make sure that the gun pressure is not set too high, so it pushes the head to a flush surface finish. Use a small punch if its is proud, and filler if its below the surface. The pins need to be positioned on the outer edge of the face, The pins will cause damage if they get positioned too close to the inside edge.

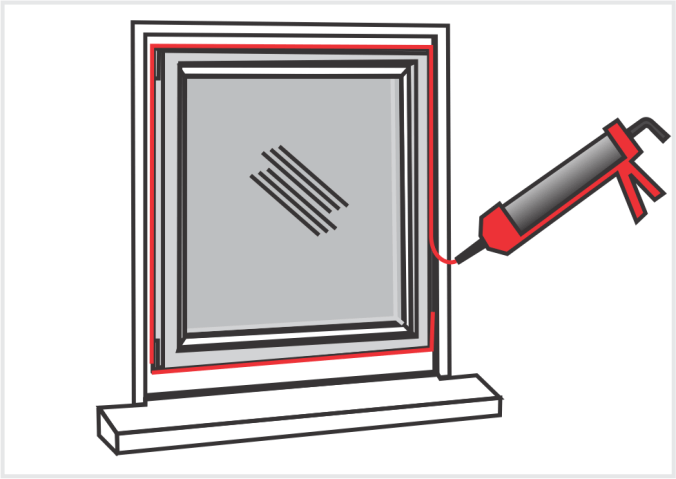

Your EVS panel needs to be sealed around the edge to prevent moisture running inside the unit. The Silicon sealer needs to be the paintable variety and will be supplied with your EVS panels. It is best to run a bead around using the corking gun, then use your finger or a rubber corner to smooth the surface for a neat presentation. Do not block the drain holes in your EVS panel.

The pin heads that are used to fix the frame are very small, but they can stick slightly above the surface rather than lie flush. You can use a nail punch to tap the pin flush but be carful not to punch it below the surface otherwise you will end up pushing it through the surface and making a hole. The Pin Heads can be rubbed over with paintable silicon

or filler, before it is painted.

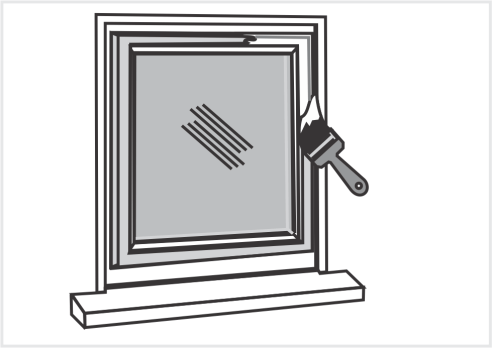

Finish by filling any small pin holes with a suitable filler, and sanding soothe if required. Your EVS panel can be painted to match your window colour using a water based paint. EVS is made of PVC-u and is recommend to use paint that is suitable for painting PVC spouting and pipes. Resene Lumbersider is especially suited to painting your EVS panels.

The EVS Step–by-Step guide, how to refurbish old timber windows back to new. Fast, simple and affordable!

Some people would think that old windows with putty falling out, a bit of rot and paint flaking off is the end of the road for old character windows, and it would be better to replace them with new aluminum windows. Before you go down that path, think of the pros and cons of installing replacement aluminum over restoring your existing timber frames with EVS.

The advantage of aluminum or PVC window replacement is that they don’t need painted and they won’t rot, the disadvantage is the extra cost and the loss of character, which could devalue your home.

The advantage of keeping your timber windows getting better insulation performance, maintaining your homes character, getting extra weather protection, and spending a lot less money. DIY improvements to your windows can provide you with a professional results while saving you even more cost.

Inspect your windows to determine how much rot requires attention. Flaking paint and putty falling out is simple to fix, but fixing rot requires more attention.

The tap test is a simple way to find rot by hitting the surface with your knuckle and if it’s a high pitch noise your timber is solid and low thud your timber has rot.

We recommend that you carve our rot rather than cut rot out. This technique is like being a dentist and inserting a filling, by drilling out the soft core and leaving the solid.

You can use a variety of tools from a drilling, cutting and grinding the rot out which leaves a very organic shape. Don’t cut square edges because they are more likely to crack later.

Paint the exposed timber with a rot treatment like Metalex or timber hardeners that penetrate into the remaining timber and prevent rot from spreading.

Use tantalized treated pine to make inserts to replace the rotten sections. (Timber decking is ideal) Cut and shape them to loosely fit back in the space. Add screws as spikes to key the bogg within the cavity.

Make sure you have your external edges inline with the external faces of the frame, so you can have timber corners to finish against. Fill the gaps with builders bog, sand and paint.

Your EVS needs to fit against the face of your timber sashes and any obstacles need trimmed back to a smooth face. The old corner pegs work their way out over time so if they are fixed then cut them.

You can spend a lot of time sanding paint back, so using a grinder sanding disk takes a lot less time. The main thing s to get rid of lose paint and paint build-ups. The key to using a grinder is to keep it moving and not let it dig groves.

Most old windows have badly painted edges and scraping them back against the putty line is important to get a good finish that looks neat. Don’t worry about chipping or dislodging old putty, get rid of any lose putty as well.

Mask your glass edges a small distance away from the putty line. This line is very visual so keep your lines as straight as you can

You can quickly mask your panels then came back and trim off the corners leaving a nice square corner cut,

Spend time to get all your masking done for the windows you are working with as you have clean fingers and getting the masking finished will minimize mess.

Corking guns come with fine nibs. This job requires a slightly larger opening to provide a good flow of silicon. Make sure the silicon says its paintable and depending on your job you can use wither white or black.

Corking the edges is a bit of a skill and you can make a big mess if not done correctly. Make sure you put a good amount where the putty has fallen out and a little amount around the other edges, to cover the putty.

The finger has been the simplest way to finish silicon, by runing it straigh over the edge you have just corked, in one stroke. Avoid multipal short strokes and leaving it too long as silicont will set and get messy. Keep your finger clean by using a rag and soapy water to smooth the silicon surface.

Speed is critical as you need to quick paint straight over the fresh silicon, before you move to the next window. Use a water based exterior primer top coat with good UV resistance. You only need to paint the putty edge and 1 cm in from the putty edges, not the whole frame.

Removing masking has to be done straight away to produce a nice sharp line finish and avoid the silicon from making strands that spoil the edge. If you wait until the paint is dry you will need to cut the edge of the masking tape with a knife before your remove the tape.

The rest of your windows can be prepared and undercoated ready of top coating after you have installed your EVS panels. You may want to double coat your inside putty edges to ensure a good coat that covers well.

Clean up any messy edges with a razor blade after the paint and silicon has dried. You can also clean the rest of the glass to remove tiny paint spots and silicon that may have landed on the surface. Each panel should have taken no longer than 20-30 minutes to get it ready for EVS glazing.

Phone: +64 (0) 3 455 0957

Email: info@evsglazing.nz